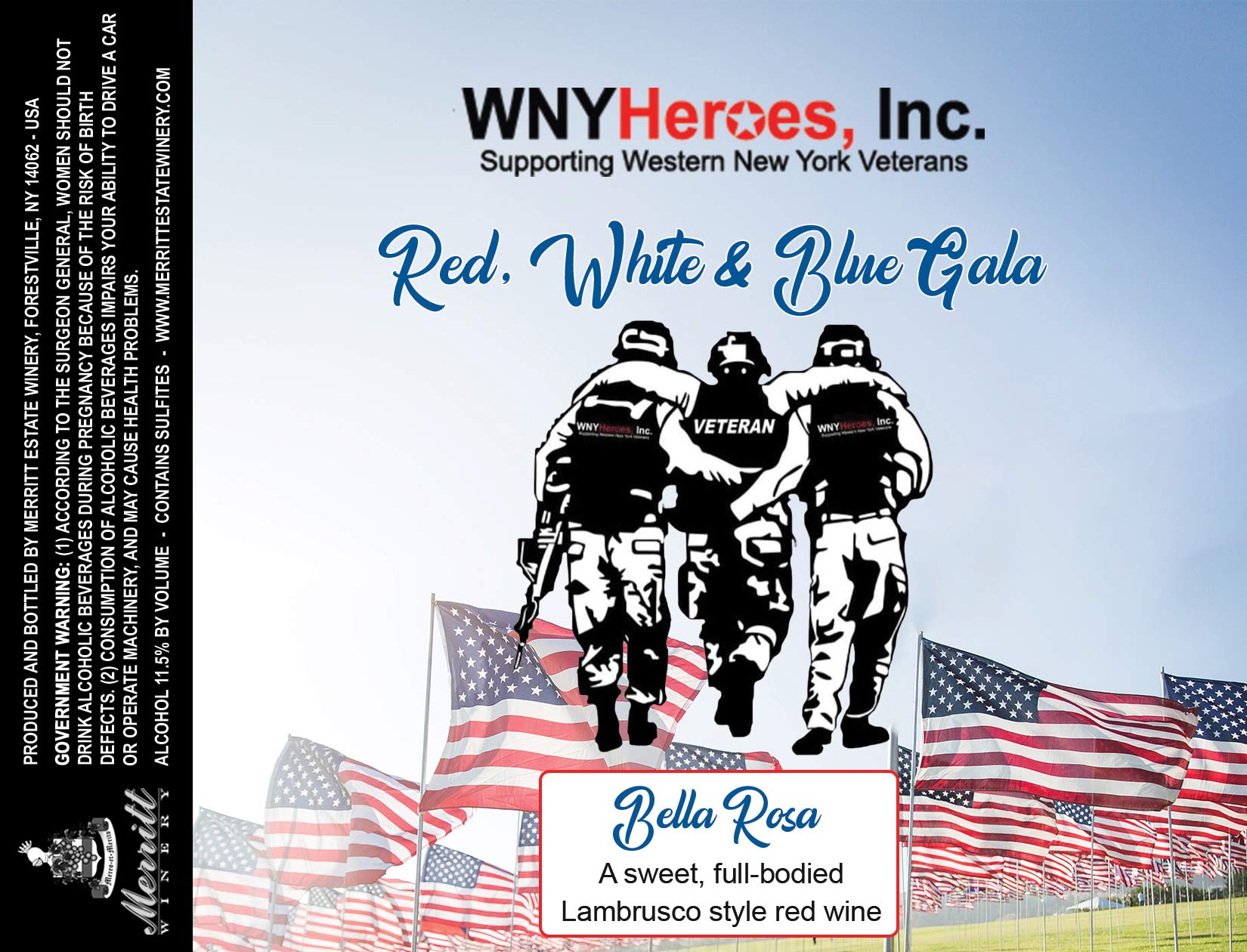

Red Wines

View Red Wine

View Red Wine

View White Wine

View Specialty Wine

View Info

We are open for Wine Tastings! Taste any 5 wines we have available for only $5! In addition, you can always enjoy any wine by the glass, local craft beers on tap, and our famous XTC & Sangria slushes during your visit. Munch on some of the specialty cheeses, crackers, and popcorn we offer for an afternoon snack. Then when you've finished your tasting, take advantage of our special Winery discounts by purchasing a few bottles.

Merritt Estate Winery participates in different events all across New York State year-round. Check back often for more information or newly added dates.